1. Ubunzulu bomngxuma kunye nobubanzi

Imingxuma kwiimeko ezininzi idityaniswe ngee-mills zokuphela, ezingagrunjwanga.Le ndlela yomatshini inika ukuguquguquka okukhulu kubungakanani bomngxuma kwisixhobo esinikiweyo kwaye ibonelela ngokugqitywa komphezulu ongcono kune-drills.Kwakhona kusivumela ukuba sisebenzise iigrooves kunye nemigodi ngesixhobo esifanayo, ukunciphisa ixesha lokujikeleza kunye nenxalenye yeendleko.Icala elisezantsi kuphela lelokuba ngenxa yobude obulinganiselweyo besixhobo sokusila, imingxuma enzulu kuneedayamitha ezintandathu iba ngumngeni kwaye inokufuna umatshini ukusuka kumacala omabini ale ndawo.

2. Ubungakanani kunye nodidi lwentambo

Ukugrumba kunye nokwenza intambo kuhambelana.Abavelisi abaninzi basebenzisa "impompo" ukusika imicu yangaphakathi.Itephu ijongeka njengesikrufu esinamazinyo kunye "nezikrufu" kumngxuma owenziwe ngaphambili.Sithatha indlela yanamhlanje yokwenza imisonto, isixhobo esibizwa ngokuba yintambo yokusila sifaka iprofayili yomsonto.Oku kudala imisonto echanekileyo kunye naluphi na ubungakanani bemisonto (imisonto nge-intshi nganye) eyabelana nge-pitch inokunqunyulwa ngesixhobo esinye sokugaya, ukugcina imveliso kunye nexesha lofakelo.Ngoko ke, iintambo ze-UNC kunye ne-UNF ukusuka kwi-#2 ukuya kwi-1/2 intshi kunye neentambo ze-metric ukusuka kwi-M2 ukuya kwi-M12 zingasetyenziswa kwisixhobo esinye.

3. Isicatshulwa kwicala

Ngaba ufuna ukukrola inombolo yendawo, inkcazo okanye uphawu kwindawo?I-acceleration ixhasa uninzi lombhalo ofunekayo ukuqhubekekiswa, ngaphandle kokuba isithuba phakathi koonobumba ngabanye kunye nemivumbo esetyenziselwa "ukubhala" ubuncinane yi-0.020 intshi (0.5 mm).Kwakhona, isicatshulwa kufuneka sibe concave kunokuba siphakanyiswe, kwaye inqaku le-20 okanye ifonti enkulu efana ne-Arial, i-Verdana okanye i-sans serif efanayo iyacetyiswa.

4. Ubude beDonga kunye noBume beFeature

Zonke iimela zethu zineemela ze-carbide.Esi sixhobo sinamandla kakhulu sinikezela ubomi besixhobo esiphezulu kunye nemveliso kunye nokuphambuka okuncinci.Nangona kunjalo, kwanezona zixhobo zinamandla zinokonakala, njengesinyithi, ngakumbi iiplastiki ezenziwa ngoomatshini.Ke ngoko, ubude bodonga kunye nobukhulu besici buxhomekeke kakhulu kwijometri yamalungu ngamnye kunye nesixhobo esisetyenzisiweyo.Umzekelo, ubuncinci bembonakalo ubukhulu be-0.020″ (0.5mm) kunye nobona bukhulu ubunzulu be-2″ (51mm) buxhaswa kumatshini, kodwa oko akuthethi ukuba ungayila isinki yobushushu ephothiweyo ngale milinganiselo.

5. Isixhobo samandla selathe

Ukongeza kwisakhono sethu sokugaya esibanzi, sikwabonelela ngesixhobo esiphilayo sokujika kwe-CNC.Izixhobo ezisetyenziswa kwaba matshini ziyafana nezo zikumaziko ethu omatshini, ngaphandle kokuba asijiki iinxalenye zeplastiki ngoku.Oku kuthetha ukuba imingxuma eccentric, igrooves, iiflethi, kunye nezinye iimpawu zingenziwa ngoomatshini ngokunxuseneyo okanye kwi-perpendicular (i-axial okanye i-radial) ukuya "kwi-axial ende" yesixhobo sokusebenza esijikiweyo (i-Z-axis yayo), kwaye ngokwesiqhelo silandele iinxalenye ze-orthogonal ezenziwe kumatshini. iziko Imithetho yoyilo efanayo.Umahluko apha kukumila kwento ekrwada, hayi isixhobo esizibekele sona.Amalungu ajikiweyo anje ngeeshafti kunye neepistons aqala ukujikeleza, ngelixa iindawo ezigudileyo ezinje nge-manifolds, iibhokisi zegeyiji kunye nezigqubuthelo zevalvu zihlala zingasebenzi, zisebenzisa iibhloko zesikwere okanye ezixande endaweni yoko.

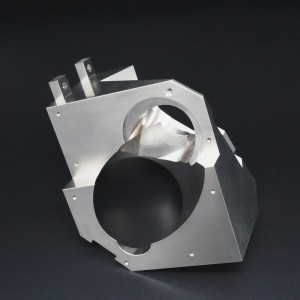

6. Multi-axis milling

Usebenzisa i-3-axis machining, i-workpiece ibotshelelwe ukusuka ezantsi kwisitokhwe ekrwada ngelixa zonke iifitsha zenxalenye zisikwe ukusuka phezulu ukuya kumacala angama-6 orthogonal.Ubungakanani benxalenye bukhulu kuno-10″* 7″ (254mm*178mm), kuphela phezulu nasezantsi kunomatshini, akukho sicwangciso sisecaleni!Nangona kunjalo, nge-five-axis indexed milling, kunokwenzeka ukuba umatshini ukusuka kulo naliphi na inani lemiphetho engekho ye-orthogonal.

Ixesha lokuposa: Feb-15-2022