BXD Manufacturing Materials

Likhetho tsa Boitsebiso

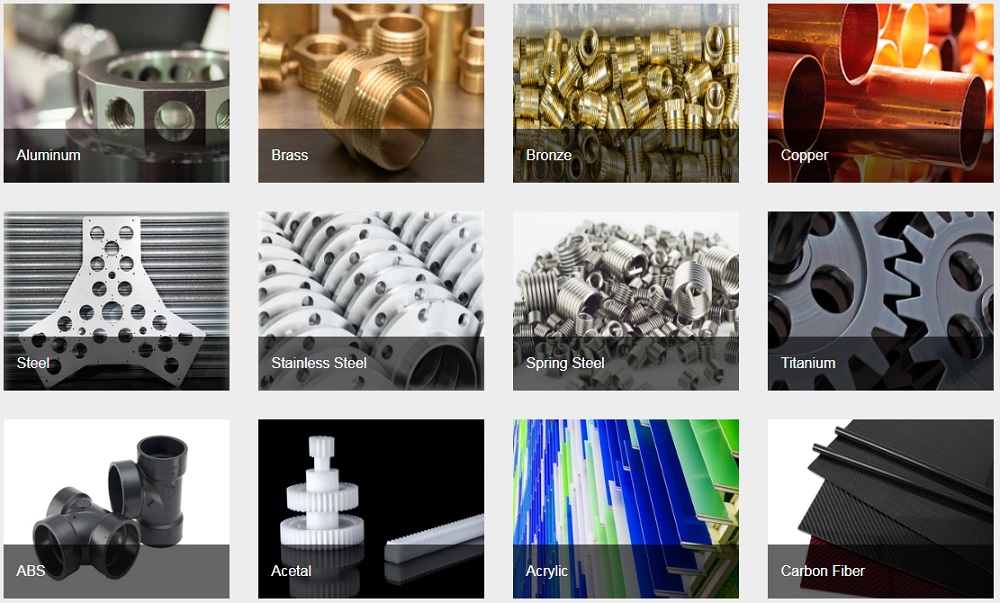

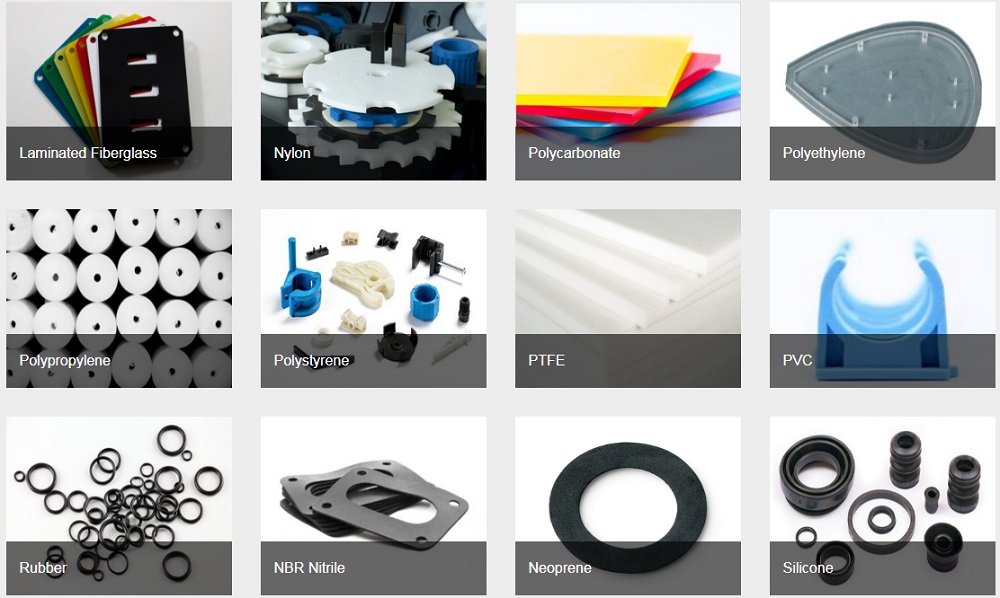

Lenane la rona la lisebelisoa le kenyelletsa likhetho tsa tlhahiso ea polasetiki, tšepe le likarolo tse ngata.Re sebetsa ka tšepe ho kenyelletsa aluminium, magnesium, tšepe, titanium, koporo le tse ling.Ntle le likhetho tsa rona tsa thepa ea setoko, BXD e ka fumana lisebelisoa tse lakatsehang mme ea fana ka machining ka lisebelisoa tse tala tse tla lumellana le ts'ebeliso e lakatsehang ea karolo ea hau.

Plastiki:ABS, ABS+PC, PC, PP, PEEK, POM, Acrylic (PMMA), Teflon, PS, HDPE, PPS, DHPE, PA6, PA66, PEI, PVC, PET, PPS, PTFE joalo-joalo.

Metal: Aluminium, Brass, Copper, Magnesium, Titanium, Stainless Steel, Tin, Zinc joalo-joalo.

Lisebelisoa tse ka holimo ke thepa e atileng haholo ea CNC prototyping le lisebelisoa tsa tlhahiso.Haeba boitsebiso bo lakatsehang bo sa thathamisoa ka holimo, ka kopo re romelle imeile.

Sehlopha se Seng

A: Tšepe

B: E seng tšepe

Lihlopha tsa tšepe:

1. Aluminium alloy, 6061/6063 / 6061-T6 / 7075/5052 / profile aluminium / die-cast aluminium, joalo-joalo.

2. Iron 45#steel/40chromium /food grade SUS304 / industrial grade SUS304 / SUS303 Titanium alloy/high carbon steel/cast iron/sheet metal, joalo-joalo.

3. Koporo e khubelu/ Boronse ba thini jj.

Nmekhahlelo ea tšepe: PEET/Imported Steel/Teflon/Bakelite/Uli Glue/Acrylic, joalo-joalo.

Bokaholimofinishing:chrome plating, nickel plating, tlhaho oxidation, sandblast oxidation, anode oxidation, color conductive oxidation, khauta plating, silevera plating, spray pente

Sebopeho sa faele:

(setšoantšo sa mahlakore a mabeli) JPG / PDF / DXF / DWG

(setšoantšo sa mahlakore a mararo) MOHATO / STP /IGS / X_T /PRT

Lisebelisoa tsa mochini oa CNC:

| Lintho tse bonahalang | E boetse e tsejoa e le | Mofuta | Mebala | Tlhaloso |

| 1018 Tšepe | Tšepe ea Khabone e Tlase ea 1018 | tšepe | Kakaretso ea Morero oa 1018 tšepe ke eona e hlahelletseng ka ho fetesisa ea litšepe tsa khabone.Likahare tsa khabone tse tlase li etsa hore ductile ena ea tšepe e be e loketseng ho etsoa le ho tjheseletsa. | |

| 4130 tšepe ea motsoako | Alloy tšepe 4130 | tšepe | E fana ka weldability e kholo ntle le ho sekisetsa ho hanyetsa.Hangata e sebelisoa ka li-gear le fasteners. | |

| Alloy tšepe 4140 | Alloy tšepe 4140 | tšepe | Chromium e eketsehileng e etsa hore tšepe ena e se ke ea bola le ho robeha. | |

| Aluminium 2024-T3 | Aluminium 2024 | tšepe | Aluminium ea 2024 e sebelisoa ha ho hlokahala karo-karolelano e phahameng ea matla ho isa ho boima, joalo ka likere, shafts le fasteners.Ha e na makenete ebile e ka phekoleha mocheso. | |

| Aluminium 5052 | Aluminium 5052 | tšepe | Aluminium e thibelang ho bola e sebelisoa khafetsa lits'ebetsong tsa tšepe. | |

| Aluminium 6061 T6 | Aluminium 6061-T6 | tšepe | Aluminium 6061 e entsoe habonolo ebile e bobebe, e loketse li-prototypes, sesole le lits'ebetso tsa sefofane. | |

| Aluminium 6063-T5 | Aluminium 6063 | tšepe | Ha tloaeleha ho sebelisoa ka ntle e le mekhabiso ea meralo ea meralo, liporo, le liforeimi tsa mamati, aluminium ea 6063 e na le machinability e betere ho feta 3003. Ha e na makenete ebile e ka phekoleha mocheso. | |

| Aluminium 7050-T7451 | Aluminium 7050 | tšepe | E ratoa ho feta 7075 aluminium hore e sebelisoe lits'ebetsong tsa meralo, 7050 ke thepa e matla e hananang le mokhathala le khatello ea maikutlo.7050 ha e na makenete ebile e ka phekoleha mocheso | |

| Aluminium 7075 T6 | Aluminium 7075 T6 | tšepe | Aluminium alloy e thata le e phahameng e ntle bakeng sa likarolo tse phahameng tsa khatello ea maikutlo. | |

| Aluminium 7075 T7351 | Aluminium 7075 T7351 | tšepe | Aluminium alloy e thata le e phahameng e ntle bakeng sa likarolo tse phahameng tsa khatello ea maikutlo. | |

| Aluminium MIC-6 | Aluminium MIC-6 | tšepe | Poleite ea aluminium e entsoeng hangata e sebelisetsoang lisebelisoa le lipoleiti tsa motheo. | |

| ASTM A36 | Letlapa la tšepe la A36 | tšepe | Morero o akaretsang, poleiti ea tšepe e kolobisitsoeng e chesang.E ntle bakeng sa lits'ebetso tsa meralo le indasteri. | |

| Brass 260 | Ho Bonolo Ho Etsa Brass 260 | tšepe | Koporo e tšabehang haholo.E ntle bakeng sa likarolo tsa radiator le lisebelisoa tsa mamati a khabisitsoeng. | |

| Brass C360 | Mahala Machining Brass C360 | tšepe | Koporo e sebetsang haholo.E ntle bakeng sa likere tsa prototyping, li-fittings, li-valve le li-screw. | |

| C932 M07 Brg Brz | E nang le Bronze C932 | tšepe | C932 ke mofuta o tloaelehileng oa boronse bakeng sa lits'ebetso tsa mosebetsi o bobebe.E sebetsa habonolo ebile e hanana le ho bola. | |

| Koporo 101 | Super Conductive Copper 101 | tšepe | Ka tloaelo e tsejoa e le Oxygen-Free Copper, alloy ena e ntle bakeng sa conductivity ea motlakase. | |

| Tloaelo | Tloaelo (Sheba Lintlha) | tšepe | Ka kopo, kenya molaetsa kapa u kopanye setšoantšo sa PDF ho qotso ena ho hlakisa boitsebiso ba hau bo tloaelehileng tabeng ea Lintlha le Metako. | |

| EPT Copper C110 | EPT Copper C110 | tšepe | Koporo ea mesebetsi e mengata e tla ka libopeho le boholo bohle.Hangata e sebelisoa lits'ebetsong tsa motlakase. | |

| Tšepe e sa hloekang 15-5 | Tšepe e sa hloekang 15-5 | tšepe | E fana ka khanyetso ea corrosion e ts'oanang le Stainless 304. Ts'ebetso e ntlafetseng, ho thatafala, le khanyetso e phahameng ea ho senya. | |

| Tšepe e sa hloekang 17-4 | Tšepe e sa hloekang 17-4 | tšepe | Alloy e matla e phahameng, e thibelang kutu.Habonolo mocheso o ka phekoleha.Ka tloaelo ho sebelisoa lisebelisoa tsa bongaka. | |

| Tšepe e sa hloekang 18-8 | Tšepe e sa hloekang 18-8 | tšepe | E 'ngoe ea litšepe tse sebelisoang ka ho fetesisa.E boetse e tsejoa e le Stainless Steel 304. | |

| Sebetsa 303 | Sebetsa 303 | tšepe | Tšepe e khonang ho sebetsa, e sa jeng. | |

| Sebetsa 304 | Sebetsa 304 | tšepe | Tšepe e khonang ho sebetsa, e sa jeng. | |

| Tšepe e se nang Mokelikeli 316/316L | Tšepe e se nang Mokelikeli 316/316L | tšepe | Tšepe e sa jeng haholo e tsebahalang bakeng sa lisebelisoa tsa bongaka. | |

| Sebetsa 416 | Sebetsa 416 | tšepe | E bonolo ho sebetsa empa e ka phekoloa mocheso ho eketsa matla le ho thatafala.Ho hanyetsa ha kutu e tlase. | |

| Stainless Steel 420 | Stainless Steel 420 | tšepe | E na le khabone e ngata ho feta Stainless 410 ho e fa boima bo eketsehileng le matla ha e phekoloa mocheso.E fana ka khanyetso e bobebe ea kutu, e hanyetsa mocheso o phahameng, le matla a ntlafalitsoeng. | |

| Tšepe A36 | Tšepe A36 | tšepe | Mohaho o tloaelehileng, tšepe ea khabone e tlase.E chesehang. | |

| Ti6Al-4V | Titanium (Ti-6Al-4V) | tšepe | Titanium e na le karo-karolelano e babatsehang ea matla ho boima, 'me lintho tse phahameng tsa aluminium tse Ti-6Al-4V li eketsa matla.Ena ke titanium e sebelisoang haholo, e fanang ka khanyetso e ntle ea kutu, ho cheseha, le sebopeho. | |

| Sehlopha sa 2 sa Titanium | Sehlopha sa 2 sa Titanium | tšepe | Matla a phahameng, boima bo tlase, le conductivity e phahameng ea mocheso.E loketse lits'ebetso tsa indasteri ea lifofane le tsa likoloi. | |

| Zinc Sheet Alloy 500 | Letlapa la Zinc | tšepe | Motsoako o sa khaotseng.E na le conductivity e ntle ea motlakase 'me e hanyetsana haholo le kutu.Alloy ena e ka phekoleha habonolo bakeng sa ho penta, ho penta le ho tlotsa anodizing. | |

| Acetal (Ntšo) | Black Delrin (Acetal) | polasetiki | Ntsho | Acetal resin e nang le khanyetso e ntle ea mongobo, e hanyetsanang le ho roala haholo, le likhohlano tse tlase. |

| Acetal (Tšoeu) | White Delrin (Acetal) | polasetiki | Bosoeu | Acetal resin e nang le khanyetso e ntle ea mongobo, e hanyetsanang le ho roala haholo, le likhohlano tse tlase. |

| Acrylic | Acrylic | polasetiki | Hlakileng | Plastiki e hlakileng e kang ea khalase.Lintho tse ntle tsa ho senya le ho senya.E ntle bakeng sa tšebeliso ea kantle. |

| ABS e Ntšo | ABS e Ntšo | polasetiki | Ntsho | Plastiki e matla ea boenjiniere e phahameng, e sebelisetsoang lihlahisoa tse ngata tsa khoebo. |

| Tloaelo | Tloaelo (Sheba Lintlha) | polasetiki | Ka kopo, kenya molaetsa kapa u kopanye setšoantšo sa PDF ho qotso ena ho hlakisa boitsebiso ba hau bo tloaelehileng tabeng ea Lintlha le Metako. | |

| G-10 Garolite (E Tletseng Lelakabe) | Garolite G10 | polasetiki | E entsoe ka resin ea epoxy e matlafatsang lesela la fiberglass, hape e bitsoa epoxy-grade laminate le phenolic, thepa ena e fana ka matla a phahameng le ho monya mongobo o tlase. | |

| Nylon 6/6 | Nylon 6/6 | polasetiki | E fana ka matla a eketsehileng a mochine, ho tiea, botsitso bo botle tlas'a mocheso le / kapa khanyetso ea lik'hemik'hale. | |

| PEKE | PEKE | polasetiki | E fana ka matla a matla a ho tsitsa, PEEK hangata e sebelisoa e le sebaka se bobebe bakeng sa likarolo tsa tšepe maemong a mocheso o phahameng, khatello e phahameng ea maikutlo.PEEK e hanela lik'hemik'hale, ho senyeha le mongobo. | |

| Polycarbonate | Hlakola Polycarbonate | polasetiki | Hlakileng | Plastiki e hlakileng kapa e mebala, e boima bo bobebe, e kang khalase e ka etsoang ka mechine. |

| Polycarbonate | Polycarbonate e ntšo | polasetiki | Ntsho | Plastiki e hlakileng kapa e mebala, e boima bo bobebe, e kang khalase e ka etsoang ka mechine. |

| Polypropylene (PP) | Polypropylene | polasetiki | Polypropylene e na le thepa e ntle ea motlakase le ho monya hanyenyane kapa ho se na mongobo.E jara meroalo e bobebe nako e telele mochesong o fapaneng haholo.E ka etsoa ka likarolo tse hlokang ho hanyetsa lik'hemik'hale kapa ho senya. | |

| PTFE (Teflon) | PTFE (Teflon) | polasetiki | Boitsebiso bona bo feta lipolasetiki tse ngata ha ho tluoa tabeng ea ho hanyetsa lik'hemik'hale le ts'ebetso ea mocheso o feteletseng.E hanela lihlapolli tse ngata 'me ke insulator e ntle ea motlakase. | |

| Polyethylene e boima ba molek'hule e phahameng haholo | UHMW PE | polasetiki | Boitsebiso ba morero ka kakaretso.E fana ka motsoako o ikhethang oa ho khathala le ho haneloa ha kutu, khohlano e tlase ea bokaholimo, matla a matla a matla, khanyetso e phahameng ea lik'hemik'hale, 'me ha e monye mongobo. |