Sheet Metal Fabrication Services

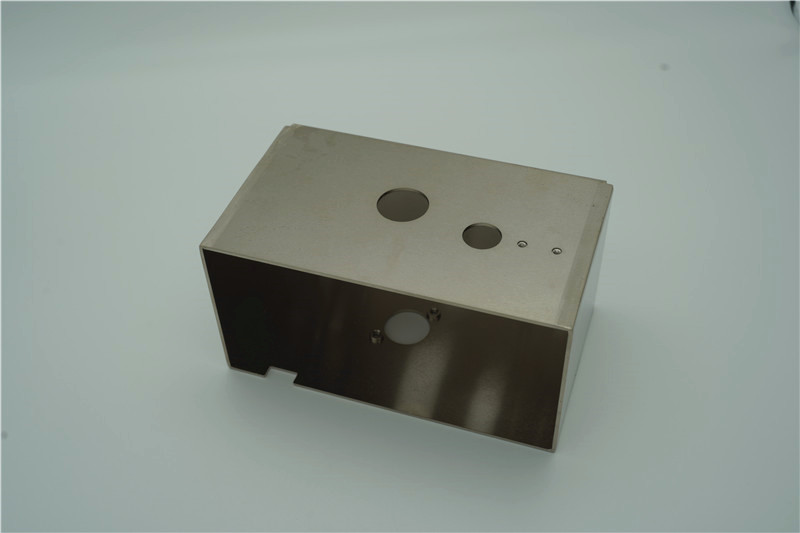

BXD's sheet metal fabrication services provide a fast and cost-effective solution for any parts that need to be made from 3D CAD files or engineering drawings. We will provide you one-stop solution for sheet metal parts and assemblies.

BXD offers a range of sheet metal materials, including aluminum, copper, steel, and stainless steel, as well as assembly services like installing PEM inserts, welding, and finishing services.

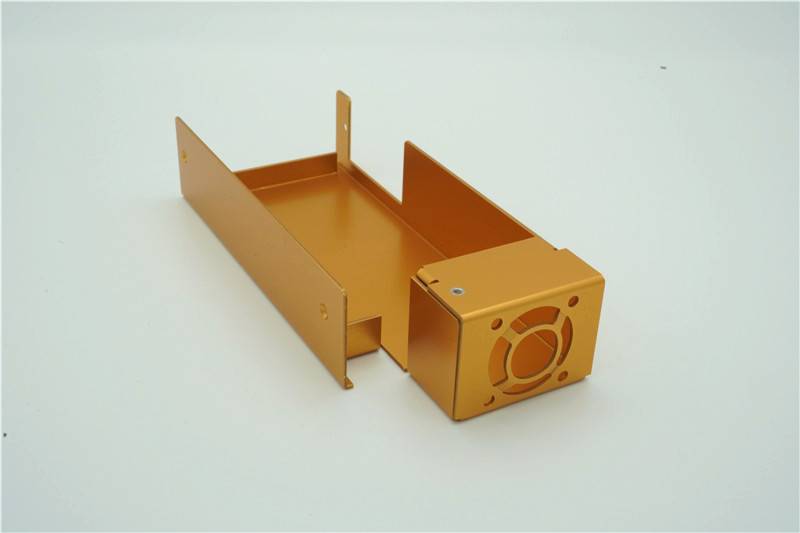

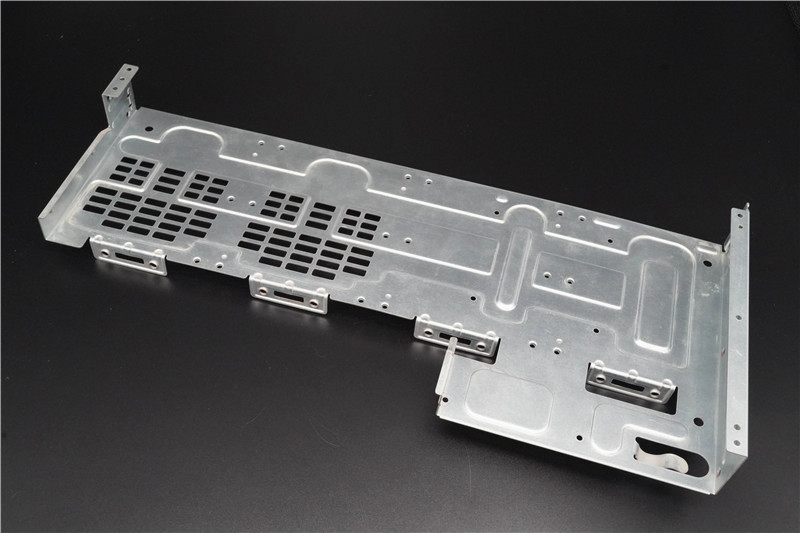

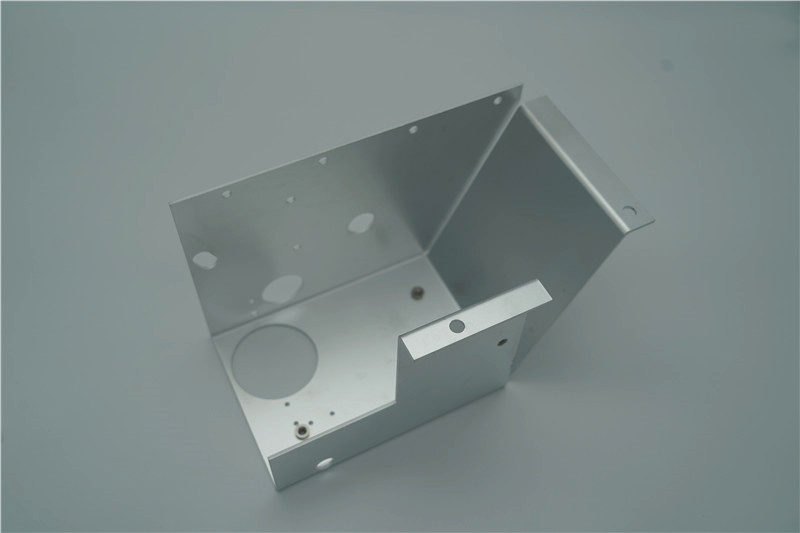

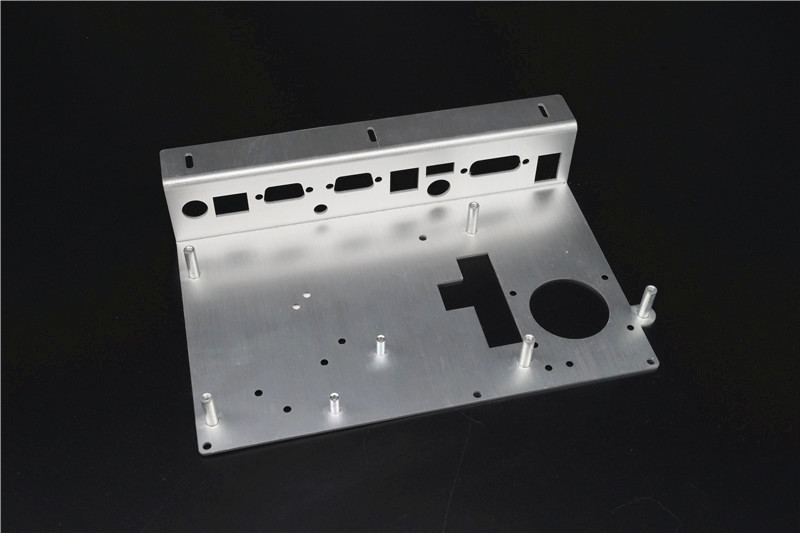

Sheet Metal fabrication is a valuable prototyping and production method for making robust functional parts like panels, brackets, and enclosures. We offers competitive sheet metal prices for low volume prototypes and cost savings for high volume production runs.

Laser cutting

Bending

Riveting

What is sheet metal fabrication?

Sheet metal fabrication is a cold working process that turning sheet metal (usually less than 6 mm) into different shape of parts. The process include shearing, punching / cutting / laminating, folding, welding, riveting, splicing, forming etc. The main feature is the same thickness of the same part.

Sheet metal fabrication can be used to create either functional prototypes or end-use parts, but end-use sheet metal parts generally require a finishing process before they are ready for market.

CNC punching machine(NCT)

Laser cutting machine

Bending machine

Hydraulic machines

Squeeze riveter

Welding machine

Sheet metal fabrication processes

-Laser cutting: sheet thickness: 0.2-6mm (depending on material)

-Oil pressure

-Pressing rivet

-Bending: sheet thickness: 0.2-6mm (depending on material)

-Welding

-Surface finishing

Available materials for sheet metal

Below is a list of our standard available metals for sheet metal fabrication. If you require a custom material please contact info@bxdmachining.com

Aluminum: 5052(H32)

Stainless steel: 304(1/2 H, 3/4H) , 316L

Mild steel: SPCC, SECC, SGCC

Copper: C11000

Tolerances for sheet metal fabrication

Below summarizes the standard tolerances of the parts produced by BXD:

Cutting feature: ±0.2mm

Bore diameter: ±0.1mm

Bend to edge: ±0.3mm

Bend angle: ± 1.0°

Available surface finishes for sheet metal

Surface finishes are applied after machining and can change the appearance, surface roughness, hardness and chemical resistance of the produced parts.

-ELECTROLESS NICKEL

-EACH AND CLEAR CHROMATE

-CLEAR ANODIZE

-BLACK ANODIZE

-HARD GOLD OVER NICKEL