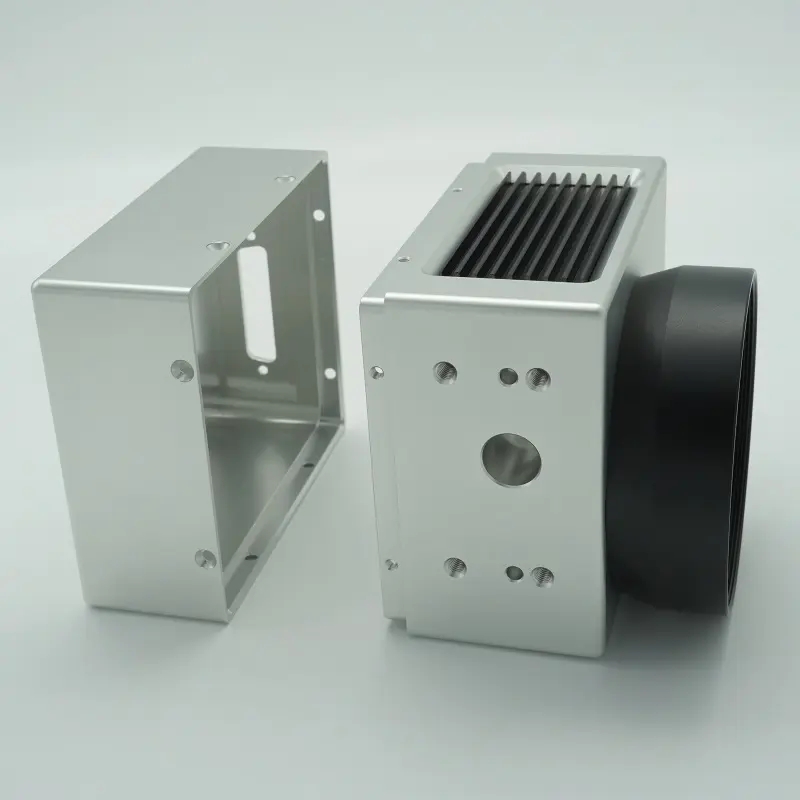

Aluminum alloy cnc processing, also known as computer gong processing or CNC machine tool processing, mainly processes aluminum parts and aluminum shells. Due to the rise of mobile phones, computers, power banks, and auto parts in recent years, there is a demand for improved processing accuracy of aluminum parts, but from the other side, the quality of aluminum alloy cnc processing technology has leaped to achieve large-scale, high-precision production of aluminum alloys. Let’s talk about the advantages of aluminum alloy CNC processing in detail.

First, the processing principle of aluminum alloy CNC:

The principle of CNC machining of aluminum alloy is to use the automatic control system to install digital program flow commands to control the automatic start and stop, reversing and speed change of the CNC machine tool bearings. The CNC blade can be selected and the amount of knife cutting and the walking trajectory can be changed according to the CNC blade to complete the life-long processing. Various auxiliary actions.

Advantages of aluminum alloy cnc processing:

① CNC machining of aluminum alloys can reduce the total number of tooling in large quantities, and produce parts with complex processing styles, only need to change the processing procedure.

②The CNC machining of aluminum alloys is relatively stable, and will not cause deviations in artificial processing, resulting in different aluminum alloys and even defective products.

③ Aluminum alloy cnc processing can produce complex aluminum parts, and even production and processing parts. It can also produce a variety of varieties, with high production efficiency, saving labor costs, and can achieve a variety of mass production at the same time

Post time: May-18-2022