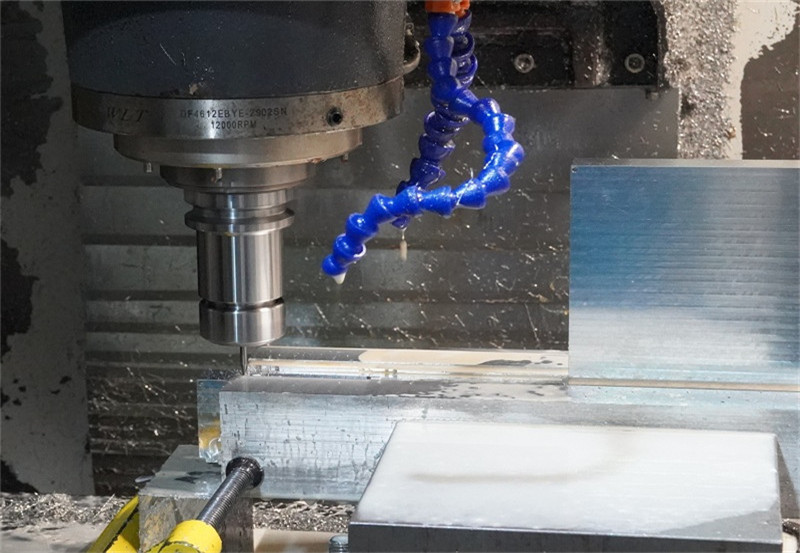

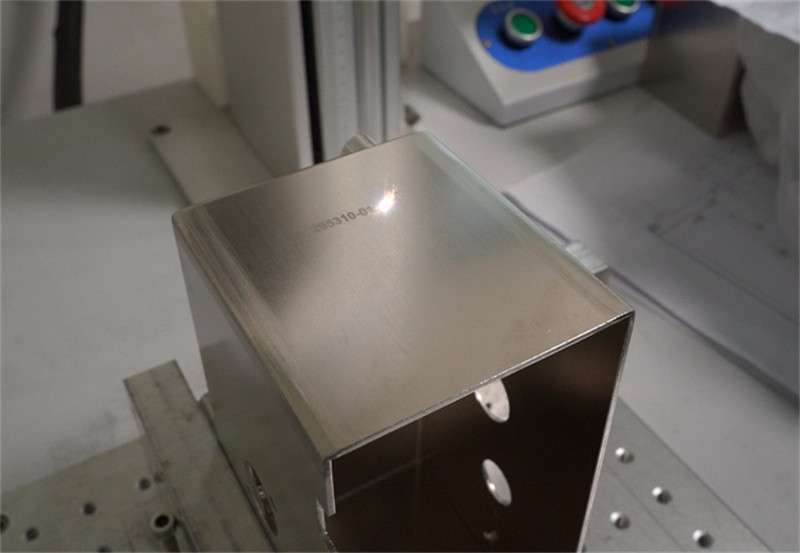

BXD muab ntau yam precision CNC machining cov kev pab cuam xws li milling, tig, EDM (electrical discharge machining) thiab hlau EDM, nto sib tsoo, laser engraving thiab ntau ntxiv.Nrog peb cov precision 3-, 4- thiab 5-axis CNC machining chaw, ua ke nrog lwm cov kev txawj ntse thiab peb pab neeg ua haujlwm, peb tuaj yeem muab cov qauv thiab cov tshuab ntim me me hauv lub sij hawm nruj thiab zoo, yog li koj pab neeg tuaj yeem tsom mus rau kev nqa koj cov khoom lag luam.

CNC tuaj yeem siv ntau yam khoom siv los ua kom tau raws li koj xav tau (ceramic, yas, ntoo, hlau, sib xyaw, ua npuas ncauj thiab iav), thiab tuaj yeem siv thoob plaws ntau yam kev lag luam.Peb kuj muaj ntau qhov thib ob machining thiab nto tiav kev pab cuam, xws li painting, txhob lo lo ntxhuav luam ntawv, txhuam, plating, polishing, sandblasting, anodizing thiab hais txog.Ntawm BXD, peb cov txheej txheem CNC machining yog siv dav hauv kev tsim cov khoom tshiab, kev siv ceev ceev, cov khoom siv prototyping thiab kev tsim khoom kawg.

Yog tias koj xav tau lub tuam txhab precision machining rau yas thiab hlau CNC machining qhov chaw, BXD yog qhov zoo tshaj plaws mus.

CNC Machining Chaw tsim tshuaj paus - BXD

Dab tsi yog CNC Machining?

Lub sij hawm CNC dav hais txog "khoos phis tawj tswj hwm tus lej" thev naus laus zis uas siv rau hauv cov txheej txheem tsim tawm.CNC machining yog cov cuab yeej tsim khoom siv nrog kev siv lub khoos phis tawj-pab tswj thiab cov cuab yeej siv tshuab kom tshem tawm cov khaubncaws sab nraud povtseg / ntu ntawm cov khoom lag luam / cov khoom ua haujlwm kom txog rau thaum qhov kev xav tau thiab qhov kawg yog tsim los ntawm cov khoom ua haujlwm.

CNC machining - Milling (3-, 4- & 5-axis)

CNC tshuab dhos-Tig tshuab

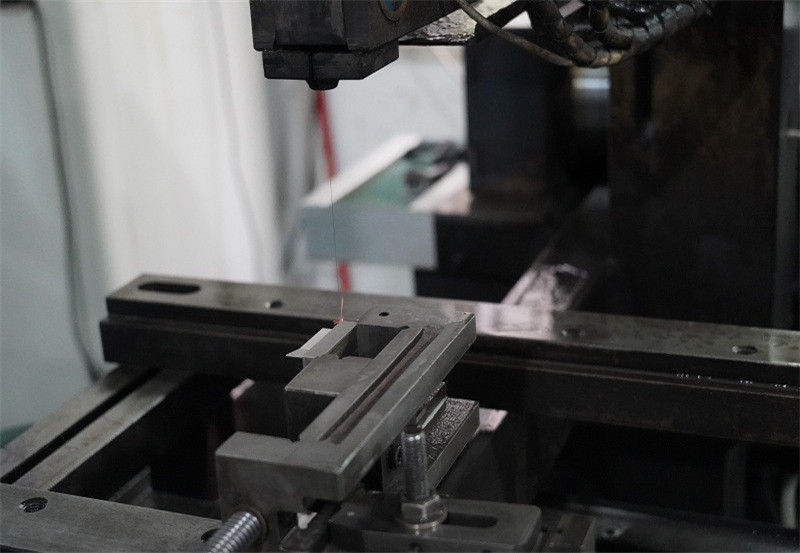

Hlau EDM

Laser npav

Nto xov

Cov txheej txheem kho saum npoo muaj xws li ntshiab anodize, dub anodized, passivation, ntshiab chromate hloov dua siab tshiab, ntshiab anodize, electroplating, siab ceev xuab zeb blasting, siab polished, deburring, du, superficial wiredrawing, thiab lwm yam.

Cov txheej txheem saum npoo muaj xws li: sawv kub, phom xim, chromium, npib tsib xee, thiab lwm yam.

Peb qhov kev ntsuam xyuas kev ua tau zoo ntawm qhov chaw tuaj yeem ua tau raws li lossis dhau cov qauv kev lag luam.

Cov khoom siv ua haujlwm:

CNC machining chaw, CNC tshuab dhos, CNC milling tshuab, CNC tig tshuab, precision grinder, EDM, hlau EDM, drilling tshuab, tapping tshuab, rivet tshuab, laser npav tshuab, ultrasonic tu tshuab, 3D CMM thiab lwm yam.

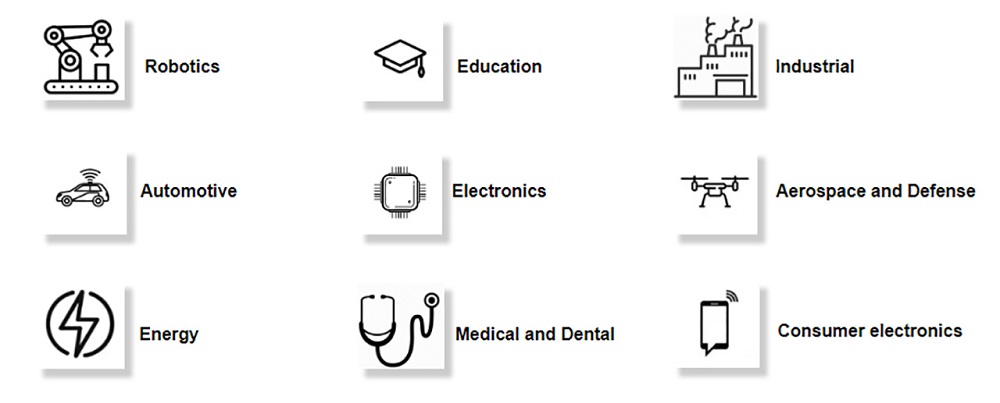

Kev lag luam ntawm CNC Machining

CNC tig thiab milling kev ua haujlwm yog qhov tseem ceeb tshaj plaws hauv ntau qhov kev lag luam thiab kev lag luam.Qee qhov kev lag luam uas CNC machining tau dav siv tau teev tseg hauv qab no:

Cov ntaub ntawv dab tsi muaj rau CNC Machining?

Yas:ABS, PC, ABS + PC, PP, PS, POM, PMMA (Acrylic), PAGF30, PCGF30, Teflon, DHPE, HDPE, PPS, PEEK thiab lwm yam.

Hlau:Aluminium, Hlau, Stainless Hlau (17-4, Inconel 625 & 718), Magnesium, Titanium, Zinc, Brass, Bronze, Copper thiab lwm yam.

Cov no yog cov khoom siv ntau tshaj plaws rau CNC prototyping thiab ntau lawm qhov chaw.Yog tias cov khoom xav tau tsis tau teev saum toj no, thov hu rau peb pab neeg.

EDM / Hlau EDM thiab nto sib tsoo

-Electrical discharge machining (EDM) yog ib qho tseem ceeb ntawm cov txheej txheem tsim khoom siv feem ntau ntawm cov cuab yeej steel rau yas txhaj tshuaj molding lossis siab tuag casting.EDM siv cov hluav taws xob graphite lossis tooj liab electrode submerged hauv dielectric da dej los yog roj.Thaum lub siab voltage tam sim no yog siv rau lub electrode nws sparks tawm tsam lub cuab tam phab ntsa, etching tam sim ntawd ntawm lub nto los tsim qhov sib sib zog nqus qhov, tav, undercuts thiab nto textures uas nyuaj rau tshuab conventionally.Thaum ua tiav zoo, EDM tuaj yeem tsim cov khoom zoo kawg nkaus nrog kev ua haujlwm nruj, tshem tawm qhov xav tau rau kev polishing theem nrab.

-Surface sib tsoo yog cov txheej txheem machining automated siv los ua cov chaw tiaj tus thiab du.Nyob rau hauv txoj kev no, lub workpiece yog tuav nyob rau hauv ib tug fixture thiab ces reciprocated hla lub ntsej muag ntawm precision sib tsoo log.

CNC Machining Tolerances

Peb muaj peev xwm muab qhov siab ntev CNC machined qhov chaw nrog tus nqi lag luam thiab super precision machined qhov chaw rau cov khoom siv high-end.Thaum ua hauj lwm nrog BXD, peb lav tag nrho cov khoom yuav ua raws li koj specification.

| Ua siab ntevStandard | |||||||

| Tolerance Lever | Zuag qhia tag nrho Dimension Range | ||||||

| Specifications | <<3,> 0.5 | <6,> 3 | <30,> 6 | <120,> 30 | <400,> 120 | <<1000,>400 | <<2000,>1000 |

| F | ± 0.05 hli | ± 0.05 hli | ± 0.1 | ± 0.15 | ± 0.2 | ± 0.3 | ± 0.5 hli |

| M | ± 0.1 | ± 0.1 | ± 0.2 | ± 0.3 | ± 0.5 hli | ± 0.8 hli | ± 1.2 |

| C | ± 0.2 | ± 0.3 | ± 0.5 hli | ± 0.8 hli | ± 1.2 | ± 2 | ± 3 |

| V | - | ± 0.5 hli | ± 1 | ± 1.5 | ± 2.5 | ± 4 | ± 6 |

3D CAD cov ntaub ntawv hom

Thov xa koj cov ntaub ntawv 3D CAD rau STEP, IGS lossis PARASOLID hom.

3D's Format:STEP (step., .stp), Solidworks.sldprt), Pro/E.prt, Inventor.ipt, CATIA.CATPart, ACIS.x_t.

2D Drawings

Peb pom zoo kom xa cov PDF Engineering Drawings rau txhua ntu.

Cov lus piav qhia screenshots qee zaum tuaj yeem lees txais.

Thov qhia txhua qhov threaded qhov, qhov loj me thiab qhov kam rau ua.

Thov sib txuas lus cov khoom thiab cov kev xav tau ua tiav (yog tias tsim nyog).

2D hom ntawv:dwg, dxf, pdf lossis zip cov ntaub ntawv xa tuaj rau peb

Vim li cas thiaj xaiv BXDrau CNC Machining Services?

Nrog rau ntau tshaj 10 xyoo kev paub hauv CNC thiab kev pabcuam machining, BXD yog ib qho zoo tshaj plaws CNC machining cov chaw tsim khoom hauv Suav teb.Nov yog vim li cas:

1. Ceev ceev tig

Qhov nruab nrab peb xa rov qab quotes hauv 24 teev, cov khoom xa tuaj hauv 7 hnub lossis tsawg dua, thiab peb muaj 99% xa khoom raws sijhawm thiab tus nqi zoo.

2. Kev paub

Peb cov engineers tau muab cov kev pabcuam CNC machining rau ntau tshaj 10 xyoo thiab tau tsim cov kev paub nplua nuj los ntawm ntau qhov haujlwm dhau los, peb tuaj yeem ua haujlwm nyuaj thiab precision yam tsis muaj teeb meem.

3.Ua kom tiavKhoom sivnrog cov khoom siv ruaj khov

BXD muaj ntau yam khoom siv hauv tsev rau kev tsim khoom thiab kev sim.Peb yuav muab cov saw hlau ruaj khov rau ib qho kev pabcuam machining rau koj los ntawm cov khoom siv raw kom tiav cov khoom.

Xav tau ib nqe lus?Tiv tauj peb tam sim no.

Thov kev tsocai pub dawb hnub no thiab peb yuav tshuaj xyuas koj qhov project hauv 24 teev.