What is CNC Milling?

CNC milling is one of the most common subtractive manufacturing processes that cut solid plastic and metal blocks into final parts.

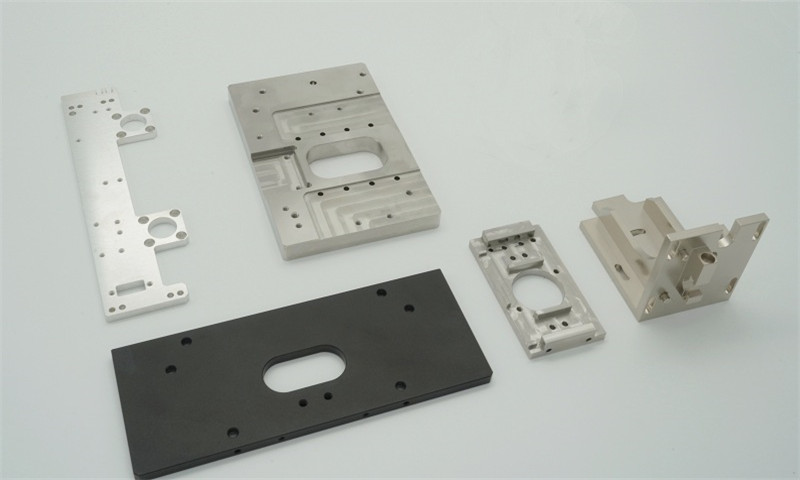

CNC milling can provide high-precision and scalable value-added services, especially for low-volume production, rapid manufacturing and rapid prototyping. And the material diversity of CNC milling also makes them very suitable for a wide range of applications in any industry.

What Does CNC Milling Work?

CNC milling uses a high-speed rotary tool or drill to remove material from the raw material while firmly holding the workpiece in the fixture. In CNC milling operation, the milling head can move along the 3-5 axis relative to the material and cut the workpiece in the way indicated by CAD / G code, while the workpiece remains stationary.

CNC milling operation includes cutting flat and shallow surface, deep cavity, flat bottom cavity, groove, thread, etc. It is capable of 3-axis (x,y and z), 4-axis and 5-axis (x,y,z, A and B) milling for high speed cutting of engineering-grade materials into product prototypes and precision end-use parts.

CNC Milling Materials

BXD CNC milling center provide various of production-grade plastic and metal materials. Such as ABS, polycarbonate, nylon ,peek ,aluminum, stainless steel , titanium ,copper etc. It is suitable for all kinds of parts applications and industries with high precision and accuracy.