China OEM Milling Auto Parts Factory Companies – Precision Aluminum Alloy 6061 CNC Milling Parts with Nickel Plating – BXD

China OEM Milling Auto Parts Factory Companies – Precision Aluminum Alloy 6061 CNC Milling Parts with Nickel Plating – BXD Detail:

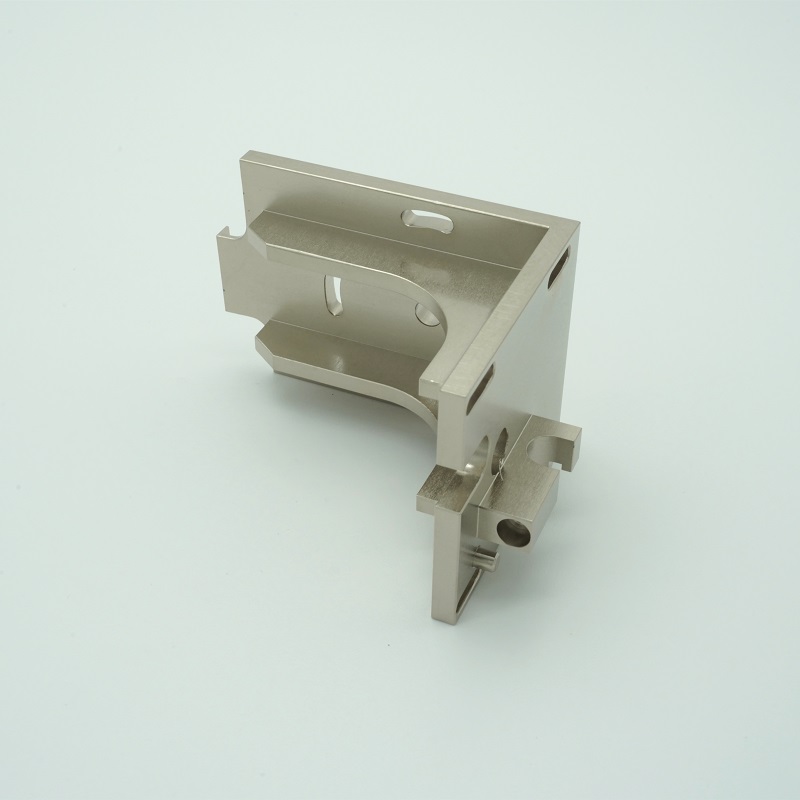

This is a socket used in automation equipment for holding the Lithium battery, It is made of 6061 aluminum alloy, which is very hard and durable. The surface is plated with nickel which can resist the corrosion of atmosphere, alkali and some acids. It can maintain its luster for a long time in the atmosphere. The hardness of nickel coating is relatively high, which can improve the wear resistance of product surface.

Step One: Product Presentation

To start, simply fill in a few information and send us a 3D CAD file.

Step Two: Quote & Design analysis

Our engineer carefully review all the technical drawing and 3D files. You’ll receive a quote shortly, and we’ll send you design for manufacturability (DFM) analysis if necessary.

Step Three: Order Confirmation and Production

Once you review the quote and order confirmed, we will select the raw material base on your requirement and standard, and our QC staff will inspect the materials before start production. Quality of raw materials is very important, it is the core of the hardware.

What are the detail manufacturing processes for making this machined part?

Firstly, as soon as the raw material was prepared, they will be transferred to CNC machining center. CNC milling is the main process used to make this aluminum holder. Secondly, we will use milling machine assist to process side holes. Thirdly, bench worker will do tapping for this product. At last, surface finishing should be applied after product passed inspection.

Step Four: Inspection

To ensure quality from start to finish, BXD provides the following inspection and review services:

♦ Incoming materials verification

♦ Design for manufacturing reviews for all quotes provided

♦ Contract reviews upon receipt of POs

♦ First article and in-process inspections

♦ Final inspections and testing with reports

We have several one-dimensional, two-dimensional and three-dimensional inspection machines, with experienced engineering team, and have our own testing room to make sure each product’s quality. All our production will be inspected by a consistent method with same standard, so we can guarantee that any parts form BXD will beyond your expectation.

Step 5: Parts are shipped!

We will pack well the product and ship out by express, air or according to your requirement.

| Material | Aluminum Alloy 6061 |

| Surface treatment | Sandblasting oxidation, anodic oxidation, natural oxidation, hard oxidation |

| Production processing | CNC machining, CNC milling, Tapping, surface finish |

| Industry | Medical industry, automation equipment industry |

| Tolerance | +/- 0.01mm |

| Drawing format | jpg / pdf / dxf / dwg / step / stp / igs / x_t / prt etc. |

| Quality assurance | - Raw material inspection: Check the raw material before accepting and storing. - In-line inspection: technicians do self-check for every parts and QC spot check during production. - Final inspection: QC 100% inspect the finished product before shipping. |

| MOQ | 1pcs |

| Sample lead time | Common products 1-10 days after received drawing and payment |

| Shipping & Delivery | By Express or By air according to customer’s requirement |

Product: Aluminum 6061 holder for automation equipment

Processes: CNC machining, CNC milling, Tapping

Surface finishing: Hard anodizing

Product: Aluminum 6061 fixture for automation equipment

Processes: CNC machining, CNC milling, Tapping

Surface finishing: Sandblasting oxidation

BXD is an ISO9001:2015 certified manufacturer, we provides a variety of precision CNC machining services including milling, turning, EDM, wire EDM, surface grinding and more, with our precision 3-, 4- and 5-axis CNC machining centers and testing equipments. We can provide prototypes and low-volume machine parts with high quality in short lead time. If you need a precision machining company for plastic and metal CNC machining parts, BXD is the best place to go.

At present, the standard and non-standard products of our company’s customers have been widely used in the automotive field, communication equipment, intelligent robot matching, medical equipment, industry 4.0 automation equipment, drones, smart toys, various LED lamps and smart Household products, etc. It can independently and satisfactorily meet the high precision and high decorative requirements of customers.

Looking for a reliable, quick-turn supplier of machined plastic and metal parts? With complete equipments, we ensure your parts are shipped on-time, every single time.

Product detail pictures:

Related Product Guide:

With our excellent management, strong technical capability and strict quality control system, we continue to provide our clients with reliable quality, reasonable prices and excellent services. We aim at becoming one of your most reliable partners and earning your satisfaction for China OEM Milling Auto Parts Factory Companies – Precision Aluminum Alloy 6061 CNC Milling Parts with Nickel Plating – BXD , The product will supply to all over the world, such as: Lisbon , Leicester , Lahore , Wide selection and fast delivery for you! Our philosophy: Good quality, great service, keep improving. We are looking forward that more and more oversea friends join in our family for further development near the future!

The company's products can meet our diverse needs, and the price is cheap, the most important is that the quality is also very nice.