China OEM Machined Metal Parts Factories Company – Custom Sheet Metal Power Box Bracket with Gold Anodizing – BXD

China OEM Machined Metal Parts Factories Company – Custom Sheet Metal Power Box Bracket with Gold Anodizing – BXD Detail:

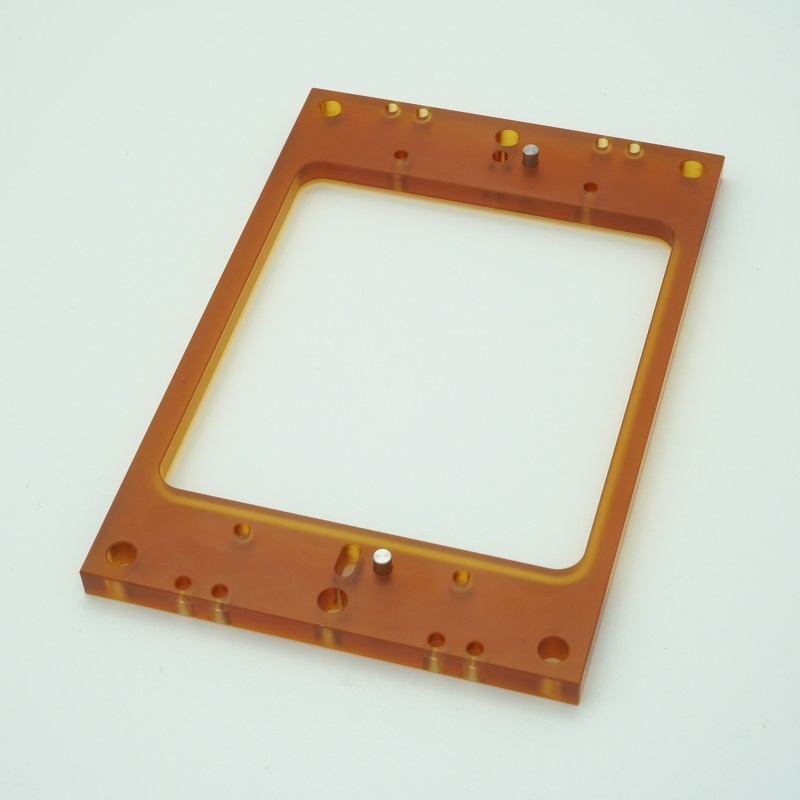

This is a PPS fixture used in a laser equipment. This kind of material is a new type of high-performance thermoplastic resin, which has the advantages of high mechanical strength, high temperature resistance, corrosion resistance, radiation resistance, flame retardancy, chemical resistance, good thermal stability, and excellent electrical properties.The heat distortion temperature is generally greater than 260 degrees, and can be used in the temperature range of 180~220℃. PPS is one of the best heat-resistant varieties of engineering plastics.

| Material | Aluminum magnesium alloy 5052-H32 |

| Surface treatment | Anodizing |

| Production processing | Laser cutting, bending, riveting |

| Industry | Household electrical appliances |

| Tolerance | +/- 0.01mm |

| Drawing format | jpg / pdf / dxf / dwg / step / stp / igs / x_t / prt etc. |

| Quality assurance | - Raw material inspection: Check the raw material before accepting and storing. - In-line inspection: technicians do self-check for every parts and QC spot check during production. - Final inspection: QC 100% inspect the finished product before shipping. |

| MOQ | 1pcs |

| Sample lead time | Common products 1-10 days after received drawing and payment |

| Shipping & Delivery | By Express or By air according to customer’s requirement |

Materials Available for Sheet Metal Fabrication

Steel: S235, S355

Stainless Steel: SS304(L), SS316(L)

Aluminum: Al5052, Al5083, Al6061, Al6082

If you require a material not listed, get in touch with our expert team to discuss your requirements. Please contact info@bxdmachining.com

FinishesAs Processed

Metal Plating

Anodizing

Powder Coating

Sheet metal fabrication processesl Laser cutting: sheet thickness: 0.2-6mm (depending on material)l Oil pressurel Pressing rivetl Bending: sheet thickness: 0.2-6mm (depending on material)l Weldingl Surface finishing

Our Laser cutting machine

Sheet metal bending

Oil press

Quality checking

Sheet metal fabrication is widely used in industries like aerospace, aviation, defense, automobile, rail, general construction, oil and gas, and more for its processing diversity, speed, and efficiency.

Choose BXD and we will successfully deliver your sheet metal project on time, to specification and without added complication. BXD sheet metal fabrication service is your one-stop-shop for making metal prototypes, custom assemblies, low and high-volume sheet metal parts in a matter of hours.

Product detail pictures:

Related Product Guide:

Our items are commonly identified and trusted by customers and may fulfill continuously switching economic and social wants of China OEM Machined Metal Parts Factories Company – Custom Sheet Metal Power Box Bracket with Gold Anodizing – BXD , The product will supply to all over the world, such as: Grenada , San Francisco , Luxembourg , Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound products with good logistics service and economical cost. Depending on this, our products are sold very well in the countries in Africa, the Mid-East and Southeast Asia.

This is a very professional and honest Chinese supplier, from now on we fell in love with the Chinese manufacturing.