China OEM CNC Turning Aerospace Parts Factories Company – Aluminum Alloy 6061 CNC Turning Parts For Lithium Battery Equipment – BXD

China OEM CNC Turning Aerospace Parts Factories Company – Aluminum Alloy 6061 CNC Turning Parts For Lithium Battery Equipment – BXD Detail:

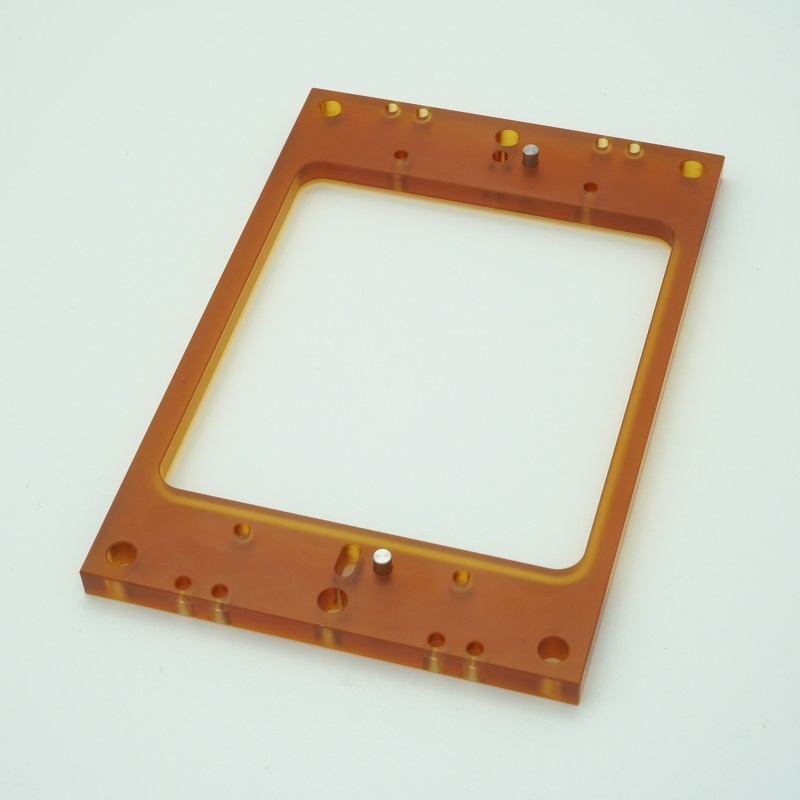

This is a sleeve used in Lithium battery equipment.

| Material | Aluminum 6061 |

| Surface treatment | nickel plating 10u” |

| Production processing | CNC turning |

| Industry | Automation equipment industry |

| Tolerance | +/- 0.01mm |

| Drawing format | jpg / pdf / dxf / dwg / step / stp / igs / x_t / prt etc. |

| Quality assurance | - Raw material inspection: Check the raw material before accepting and storing. - In-line inspection: technicians do self-check for every parts and QC spot check during production. - Final inspection: QC 100% inspect the finished product before shipping. |

| MOQ | 1pcs |

| Sample lead time | Common products 1-10 days after received drawing and payment |

| Shipping & Delivery | By Express or By air according to customer’s requirement |

Product: Mercury slide ring cover

Material: Stainless Steel SUS304

Surface finishing: Natural color without surface treatment

Industry: Lithium battery equipment industry

Custom CNC Turning Services – OEM China CNC Turning Parts Manufacturer & Company

BXD is an experienced precision CNC turning services supplier, manufacturer, exporter in China, has been specialized in offering best OEM CNC lathe services for superior quality low cost CNC turning parts, CNC lathe parts or high precision machined components with the operation of an impressive range of state-of-the-art turning machines, such as washers, bolts, shafts, rivets, spacers, sleeves, nipples, stainless steel fittings, pipe fittings, light fittings, wheel studs, etc.

Our advanced CNC turning center routinely works with a wide variety of materials, ranging from copper, brass, stainless steel, carbon steel, aluminum, and titanium. We can always choose a suitable precision turning process to reach your requirements. Our custom CNC machining services ensure that our customers receive the highest quality CNC turned parts. Send your inquiry or drawing fast to get an quick CNC quote.

Product detail pictures:

Related Product Guide:

Our mission should be to turn out to be an innovative supplier of high-tech digital and communication devices by furnishing benefit added design and style, world-class manufacturing, and repair capabilities for China OEM CNC Turning Aerospace Parts Factories Company – Aluminum Alloy 6061 CNC Turning Parts For Lithium Battery Equipment – BXD , The product will supply to all over the world, such as: Somalia , Canada , Houston , We have advanced production technology, and pursuit innovative in products. At the same time, the good service has enhanced the good reputation. We believe that as long as you understand our product, you must be willing to become partners with us. Looking forward to your inquiry.

Factory equipment is advanced in the industry and the product is fine workmanship, moreover the price is very cheap, value for money!