China OEM China Plastic Case Prototype Factory Companies – PEI Clamper CNC Plastic Parts CNC Machining – BXD

China OEM China Plastic Case Prototype Factory Companies – PEI Clamper CNC Plastic Parts CNC Machining – BXD Detail:

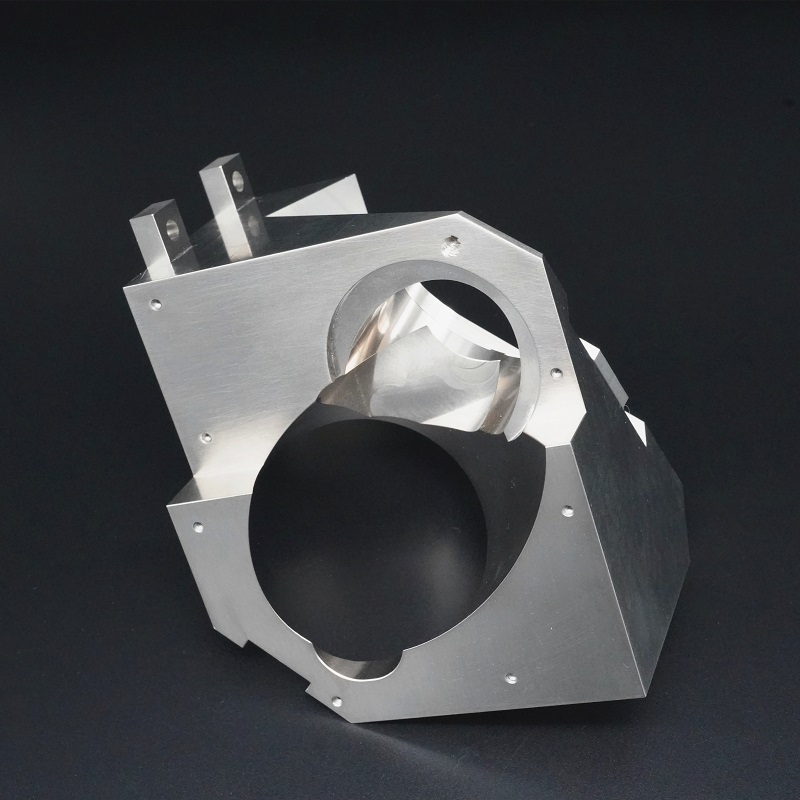

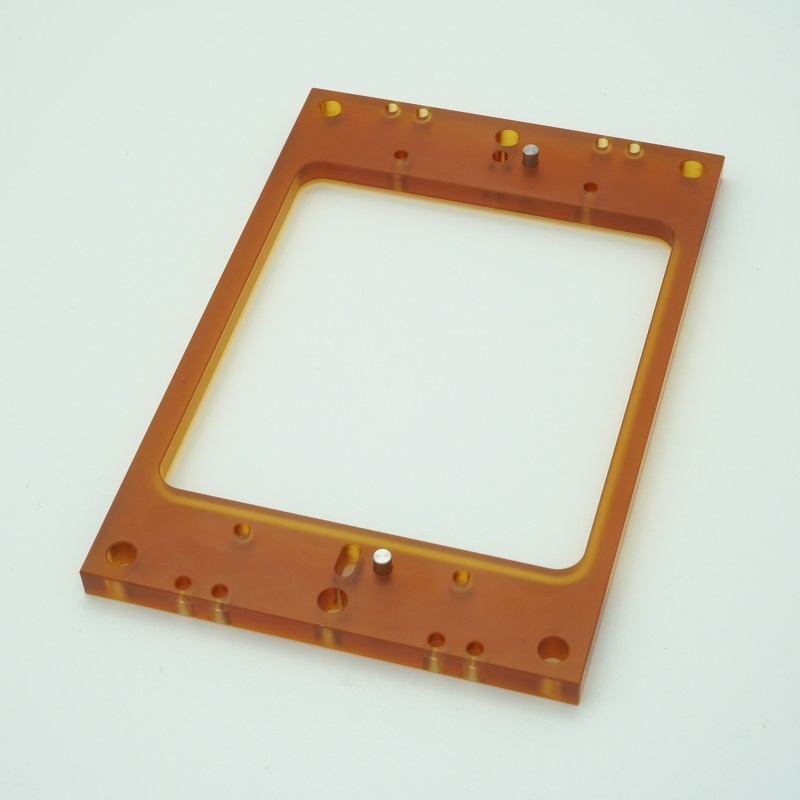

This is a clamper made with PEI, it used in advanced electromechanical equipment. The material PEI has the best high temperature resistance and dimensional stability, as well as chemical resistance, flame retardancy, electrical properties, high strength, high rigidity, etc. Not only has high mechanical performance, but also has excellent heat resistance and chemical stability (continuous use temperature is about 170 ℃)

| Material | PEI- Polyetherimide |

| Surface treatment | Natural color without surface treatment |

| Production processing | CNC machining, CNC turning, Tapping, assembly |

| Industry | Electromechanical equipment industry |

| Tolerance | +/- 0.01mm |

| Drawing format | jpg / pdf / dxf / dwg / step / stp / igs / x_t / prt etc. |

| Quality assurance | - Raw material inspection: Check the raw material before accepting and storing. - In-line inspection: technicians do self-check for every parts and QC spot check during production. - Final inspection: QC 100% inspect the finished product before shipping. |

| MOQ | 1pcs |

| Sample lead time | Common products 1-10 days after received drawing and payment |

| Shipping & Delivery | By Express or By air according to customer’s requirement |

A broad range of plastics for CNC machining along with applications in different industries. Ideal for both end-user custom parts and one-off prototypes.

POM (Delrin/Acetal)

High stiffness, low friction, high accuracy, easy to machine.

Nylon

Excellent mechanical features, chemical, thermal, and abrasion-resistant.

ABS

Common thermoplastic, easy to machine, and impact resistant.

PEEK

Very high strength, High-performance thermoplastic, thermal and chemical resistant.

PTFE (Teflon)

Low friction, thermal, and chemical resistance.

Polycarbonate

High toughness, transparency, and excellent impact strength.

Polyethylene

Excellent ratio of strength-to-weight, weather, and impact-resistant.

PVC

Excellent weather and chemical resistance and good toughness.

PMMA (Acrylic)

Transparent rigid plastic is used as a substitute for glass.

PET

Tough plastic and offers brilliant mechanical strength and wear resistance.

Polypropylene

Excellent chemical resistance. Food-safe grades are available.

G-10

Low moisture absorption, high strength, and high-level of chemical resistance and electrical insulation.

FR4

Glass fiber flame retardant epoxy laminate.

Product detail pictures:

Related Product Guide:

Our commission should be to provide our customers and consumers with ideal top quality and aggressive portable digital products for China OEM China Plastic Case Prototype Factory Companies – PEI Clamper CNC Plastic Parts CNC Machining – BXD , The product will supply to all over the world, such as: Johor , Gabon , Paris , Our items are exported worldwide. Our customers are always satisfied with our reliable quality, customer-oriented services and competitive prices. Our mission is "to continue to earn your loyalty by dedicating our efforts to the constant improvement of our merchandise and services in order to ensure the satisfaction of our end-users, customers, employees, suppliers and the worldwide communities in which we cooperate".

The customer service staff's answer is very meticulous, the most important is that the product quality is very good, and packaged carefully, shipped quickly!