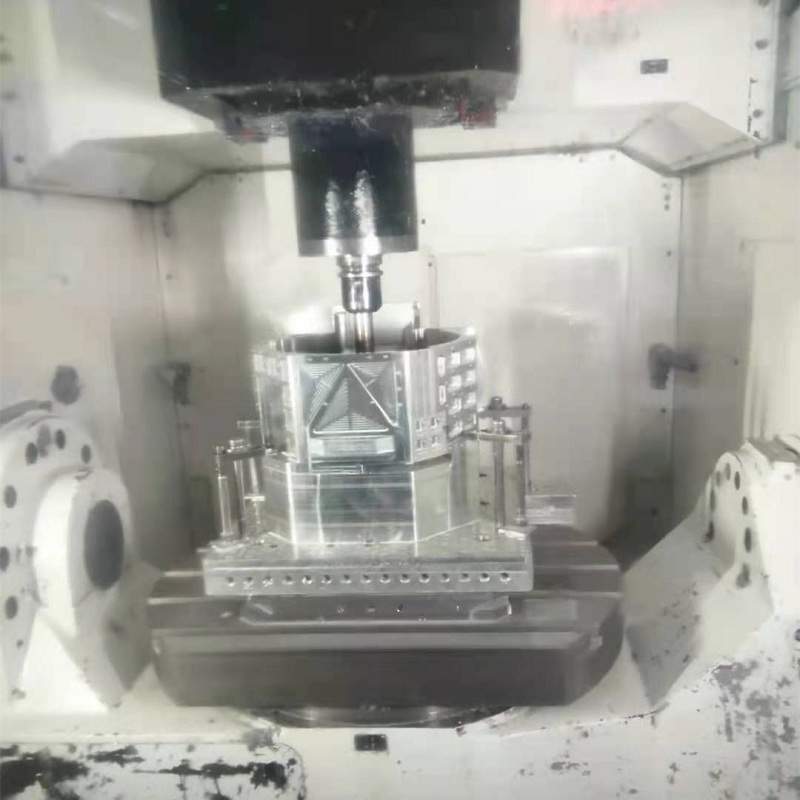

5 Axis CNC Machining for complex parts

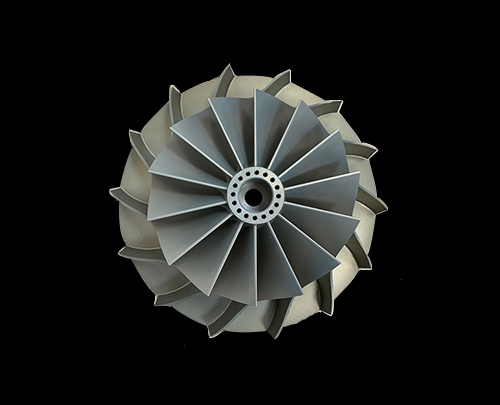

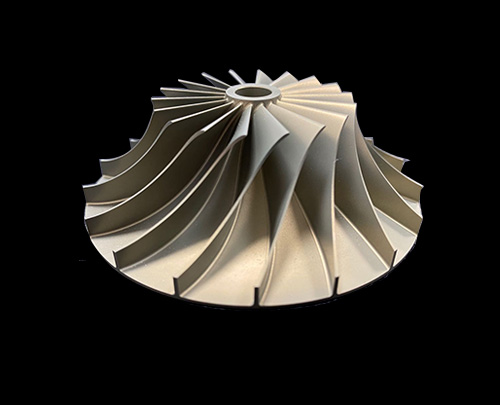

The 5 axis machining is a high-tech, high-precision machining center specially used to process complex curved surfaces. It is very important to a country’s aviation, aerospace, military, scientific research, precision equipment, high-precision medical equipment etc. The five-axis CNC machining center system is the only means to solve the processing of impellers, blades, marine propellers, heavy generator rotors, steam turbine rotors, large diesel engine crankshafts, etc.

5 Axis CNC machining services

BXD 's 5 Axis CNC machining capabilities allow for parts with extreme multi-axis complexity to be machined. We have advanced 5 axis equipment, knowledge and expertise, whether you require a single part or mass production, trust us to manage the entire process for you.

Product name: Three-dimensional copper processing

Material: copper

Surface finishing: Deburring

Precision: +/-0.02

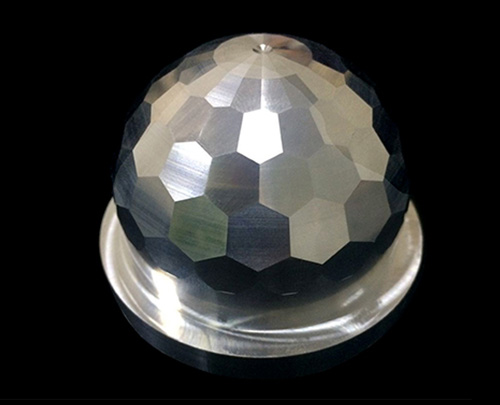

Product name: Optics parts processing

Material: Aluminum alloy 6061

Surface finishing: Mirror polishing

Precision: +/-0.02

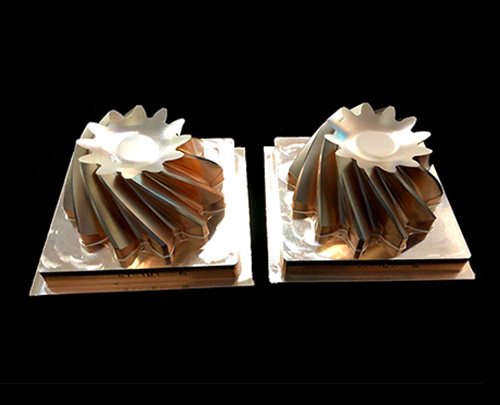

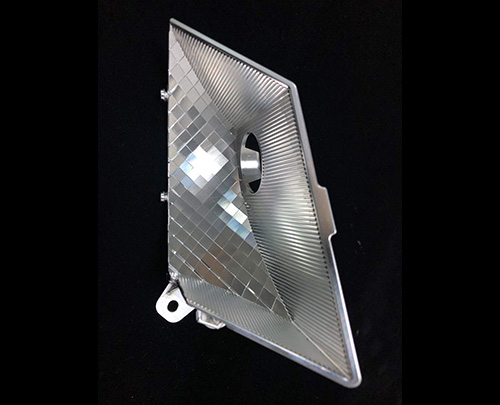

Product name: Car lighting reflect bowl processing

Material: Aluminum alloy 6061

Surface finishing: Vacuum aluminum plating

Precision: +/-0.02

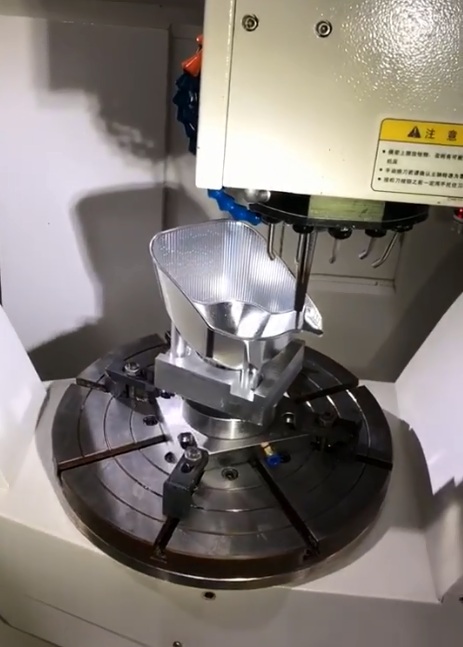

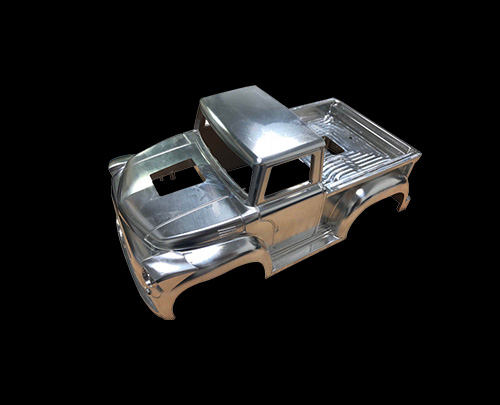

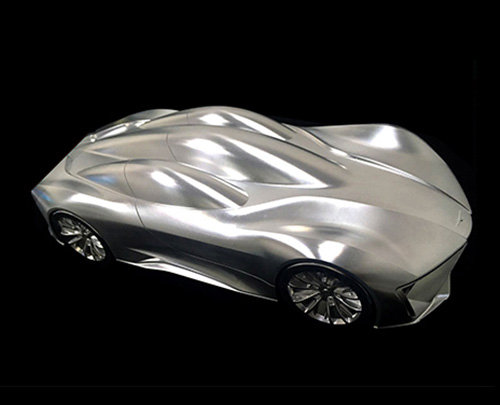

Product name: Car mould processing

Material: Aluminum alloy 6061

Surface finishing: Deburring

Precision: +/-0.05

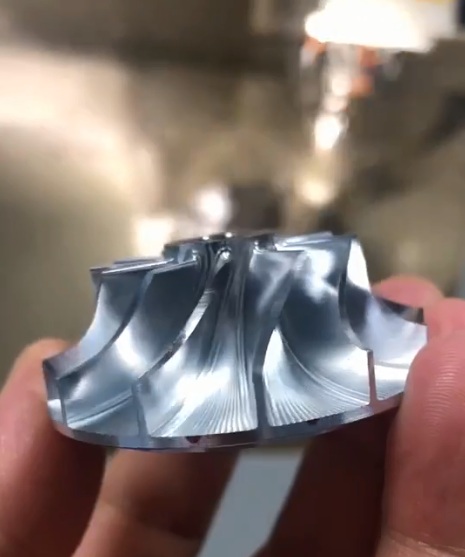

5 Axis impeller machining

5 Axis dolphin machining

5 Axis inner diagonal gear

5 Axis nest building machining

5 Axis artwork machining

5 Axis roller machining

5 Axis peek parts machining

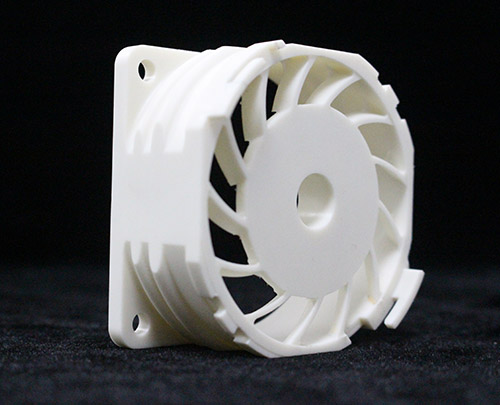

5 Axis blower wheel machining

5 Axis car model machining

5 Axis cooling fan machining

5 Axis camera lens machining

5 Axis golf model machining

-High precision

-Competitive pricing

-Fast turnaround

-Multi-axis capability